Classification by Spray Method

Spray dryer is a one-step direct drying method from raw material solution to finished powder.

Spray Dryers Comparison

When comparing spray dryers, some of the factors that should be considered include: material characteristics, capacity, energy efficiency and cost.

- The power consumption of the centrifugal spray dryer is between pressure and closed loop spray dryers. It is suitable for high-viscosity or liquid with solids, the output can be adjusted within +25% of the designed capacity without affecting product viscosity. It occupies a smaller area, has a larger capacity, and is more convenient to maintain. Its disadvantages are high manufacturing costs, thicker droplets, and larger nozzles, so the diameter of the spray dryer tower is correspondingly much larger than that of the other two spray dryers.

- The power consumption of the pressure spray dryer is the lowest (about 4-10kw/h). It is suitable for the feed liquid of general viscosity. The disadvantage is that it must have a high-pressure pump, the nozzle is small and easy to clog, and the production adjustment range is narrow. In addition, the pressure spray dryer is much higher, so the construction cost will be higher.

- The power consumption of the airflow spray dryer, is the largest, and about 0.4-0.8 kg of compressed air is needed for each kg of feed liquid. However, its structure is simple and easy to manufacture, and it is suitable for any viscosity or slightly solid feed liquid.

For more details, please check the comparison chart below.

Items | Centrifugal Spray Dryer | Pressure Spray Dryer | Air Flow Spray Dryer | |

Material Characteristics | Capacity Adjustment Range | Wide | Narrow | Medium |

High-Viscosity | ✓ | ✕ | ✕ | |

Feeding System | Pressure | Low Pressure, About 3kgf/cm2 | High Pressure, 10~200kgf/cm2 | Low Pressure, About 3kgf/cm2 |

Need High-Pressure Pump? | ✕ | ✓ | ✕ | |

Atomizer | Maintenance | The high-speed rotating device is high precision and difficult to maintenance | The nozzle is easy to wear, and the high pressure pump needs maintenance | Easy |

Power Consumption | Medium | Low | High | |

Final Products | Granularity | Fine-grained | Coarse-grained | Coarse-grained |

Uniformity | ✓ | Roughly | ✕ | |

Bulk Density | Light, the pores of the particles are spherical | Heavy, less air content in the particles | N/A | |

Drying Tower | Hot Air Flow Directions | Countercurrent | Cocurrent, Countercurrent and Mixed | Cocurrent and Countercurrent |

Tower Diameter | Large | Small | Small | |

Tower Height | Low | High | Medium | |

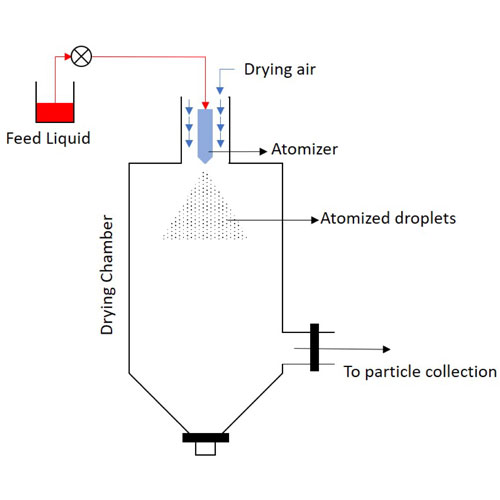

The Parts of Spray Dryers

For different materials or requirements, the spray drying machine systems we design are also different, but these following 5 main basic units are indispensable.

- Feeding system - Depending on the form of the atomizer used and the nature of the material, the feeding method is also different. Commonly used feeding pumps include screw pumps, metering pumps, and diaphragm pumps.

- Heating system - The most important factor in the selection of the heating system is the characteristics of the liquid material. The heating equipment mainly has two types: direct heat supply and indirect heat exchange.

- Atomization system - The atomization system is the core of the entire spray drying system. There are three common types: Centrifugal type - the centrifugal force generated by the high-speed rotation of the machine is the main atomization power; Pressure type - the high pressure generated by the feeding pump is the main atomization power; Air flow type - the kinetic energy generated by the airflow is the main atomization power.

- Drying system - The type of the dryer depends to some extent on the atomizer. It is also a major part of the spray drying design.

- Gas-solid separation system - After the droplets are dried to remove most of the water, they form powder particles, some of which are separated from the gas at the bottom of the drying tower and discharged, and the other part enters the gas-solid separation system with the tail gas and needs to be further separated. There are mainly two types of gas-solid separation: dry separation and wet separation.

Atomizer Selection Criteria

Atomizers are used to break down liquids into small droplets or mist. When selecting an atomizer, there are several criteria to consider.

Items | Centrifugal Atomizer | Pressure Atomizer | Air Flow Atomizer | |

Dryer Tower | Cocurrent | ✓ | ✓ | ✓ |

Countercurrent | ✕ | ✓ | ✓ | |

Mixed | ✕ | ✓ | ✓ | |

Liquid Properties | Low Viscosity | ✓ | ✓ | ✓ |

High Viscosity | ✓ | ✕ | ✓ | |

Non-abrasive | ✓ | ✓ | ✓ | |

General Abrasive | ✓ | ✓ | ✓ | |

High Abrasive | ✓ | ✕ | ✕ | |

Paste (Pumpable) | ✓ | ✓ | ✓ | |

Feeding Speed | ≤3 m3/h | ✓ | ✓ | ✓ |

>3m 3/h | ✓ | Conditional | Conditional | |

Droplet Size | 30~120 μm (400~115 mesh) | ✓ | ✕ | ✓ |

120~250 μm(115~60 mesh) | ✕ | ✓ | ✕ | |

Spray Dryer Applications

Spray Drying in Food Industry

Spray drying is a widely used process in the food industry to produce powders from liquids, including dairy product powder (such as milk and whey), coffee and tea extracts, fruit and vegetable powders, vitamins, starches, carbohydrates, flavors and seasonings.

Spray Drying in Pharmaceutical Industry

Spray drying is particularly useful in the pharmaceutical industry as it enables the production of consistent powders with controlled particle size and morphology. These powders are ideal for the formulation of inhalation products, oral solid dosage forms, and topical formulations.

Spray Drying in Ceramic Industry

Spray drying is an efficient method for producing ceramic powders, as it allows for the production of uniform particles with precise control over particle size and shape. This is particularly important in the production of advanced ceramics, which require high levels of purity and uniformity.

Get In Touch With Us

FAQs

Where Is Your Factory?

We are located in Changzhou City near Shanghai.

What's The Quality Of Your Machine?

Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process. You can rest assured of the quality absolutely.

What Is The Warranty Period?

24 hours timely response to mail and phone calls. We will provide a one-year warranty to make sure your machine runs consistently.

What Is The Payment Term?

Our regular payment term is 30% TT in advance, 70% TT before shipment.

Does Your Price Include Freight?

Our usual price is based on FOB Shanghai. We can provide a CIF quote upon request.