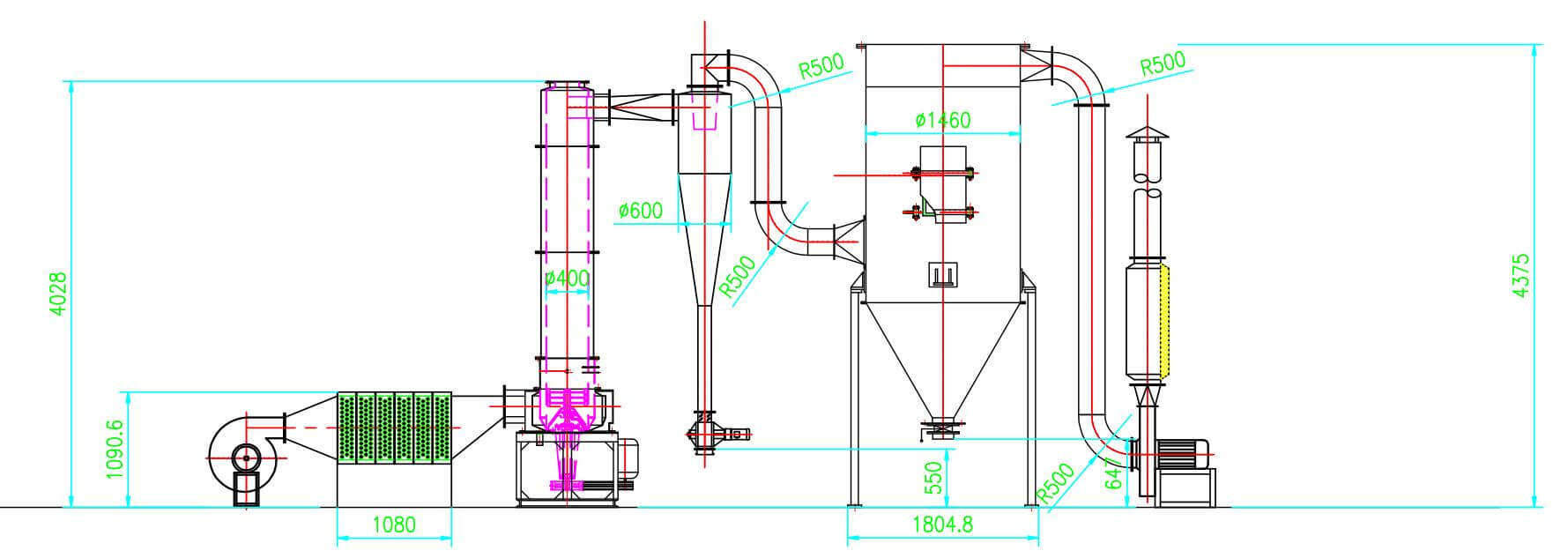

Spin Flash Dryer Flow Chart

The spin flash dryer is composed of a hot air distributor, a drying cylinder, a classifier and a screw feeder.

1. Hot Air Distributor

The hot air distributor is a volute tangential uniform air inlet.

2. Drying Cylinder

The drying cylinder can be divided into four zones from bottom to top: agitation flash drying zone, rotary fluidized drying zone, airflow drying zone, and classification zone.

- Agitation Flash Drying Zone: The stirring and flash drying zone is located at the bottom of the drying cylinder, which can evaporate 60% to 80% of the water in the material. The speed of the agitator is adjustable, generally 200-500r/min, the diameter of the drying cylinder is large, the speed is low; on the contrary, the diameter is small, the speed is high.

- Rotary Fluidized Drying Zone: The rotary fluidized drying zone is located in the middle of the drying cylinder close to the cylinder wall. In the agitation and flash drying zone, the material particles are driven by the rotating air flow to spiral up and enter the rotating fluidized drying zone, so that the particles are further reduced.

- Airflow Drying Zone: The airflow drying area is located in the middle of the upper part of the drying cylinder, which is a solid particle dilute phase area. In this drying zone, when the airflow velocity is greater than the suspension velocity of material particles, the material is brought to the classification area.

- Classification Zone: The classification area is located on the top of the drying cylinder. The simplest classifier is an elutriation ring. If the radius of the material particle is smaller than the radius of the elutriation ring, the material will be taken out of the drying cylinder to complete the drying process, then re-enter the rotary fluidized drying zone for further drying.

3. Classifier

The simplest classifier is the elutriation ring mentioned above. This is a fixed classification device, elutriation rings with different inner diameters can only allow particles smaller than a certain diameter to pass through. Elutriation rings should be replaced when diameter requirements change.

The other is to install a rotary classification device with adjustable speed on the position of the elutriation ring. As long as the speed is changed, particles with different particle sizes can be allowed to pass through. The higher the speed, the smaller the particle size that passes through.

4. Screw Feeder

When the material is loose, the traditional single screw feeder can be used; when the material is slightly sticky, the screw feeder with crushing can be used; when the material is more viscous, the double screw feeder can be used.

The speed of the screw feeder is adjustable, please contact us for the design of the feeder with general speed.

Technical Parameters

| Model | Cylinder diameter(mm) | Size(mm) | Power(kw) | Handling air volume (m3/h) |

Evaporated water(kg/h) | Floor area(m2) |

| XSG-2 | 200 | 250 × 2800 | 2.2 | 350~600 | 10~20 | 15 |

| XSG-3 | 300 | 400 × 3300 | 3 | 800~1300 | 20~50 | 15 |

| XSG-4 | 400 | 500 × 3500 | 5.5 | 1400~2300 | 25~70 | 20 |

| XSG-5 | 500 | 600 × 4000 | 5.5 | 2100~3600 | 30~100 | 25 |

| XSG-6 | 600 | 700 × 4200 | 5.5 | 3000~5100 | 40~200 | 28 |

| XSG-8 | 800 | 900 × 4600 | 7.5 | 5500~9000 | 60~600 | 25 |

| XSG-10 | 1000 | 1100 × 5000 | 11 | 8500~14000 | 100~1000 | 55 |

| XSG-12 | 1200 | 1300 × 5200 | 15 | 12200~20000 | 150~1300 | 75 |

| XSG-14 | 1400 | 1500 × 5400 | 18.5 | 17000~27700 | 200~1600 | 85 |

| XSG-16 | 1600 | 1700 × 6000 | 22 | 22000~36000 | 250~2000 | 100 |

XSG-8 Spin Flash Drying Solution (e.g. MHEC)

1. Customer Materials & Requirements | |||

Material Name | MHEC | Dust Removal System | Cyclone + bag dust collector |

Capacity | 1000kg/h | Equipment Material | Material contact part 304, the rest A3 |

Initial Moisture | 10%(wet base) | Installation Site | Indoor |

Final Moisture | 0.5%(wet base) | Power Supply | 380V 50HZ |

Specific Gravity | 0.5g/cm3 | Environment | 15℃, 760mmHg, φ=75% |

Heat Source | Steam 0.8MPa | ||

2. Equipment Configuration List | ||||

ID | Equipment Name | Models & Specifications | Material | Quantity |

1 | Ⅰ Air Filter | A3 Steel/non-woven | 1 | |

2 | Blower | 4-72 5A | A3 Steel | 1 |

3 | Steam Heat Exchanger | SRZ12X7D | Q235 Steel/Al | 6 |

4 | Hot Air Inlet Duct | SUS304 | 1 | |

5 | Flash Drying Machine | XSG-8 | Material Contact Part SUS316L | 1 |

6 | Equipment Base | 0~350 | Material Contact Part SUS316L | 1 |

7 | Spiral Feeder | LJQ-159 | Material Contact Part SUS316L | 1 |

8 | Cyclone Dryer | XF-600 | Material Contact Part SUS316L | 1 |

9 | Cyclone Bag Dust Collector | MC-86 | Material Contact Part SUS316L | 1 |

10 | Automatic Discharger | TFGF-12L | 304 | 1 |

11 | Exhaust Duct | A3 | 2 | |

12 | Induced Draft Fan | 9-26 9D | A3 | 1 |

13 | Chimney Duct | Q235 | 1 | |

14 | Electric Control Cabinet | Plastic Spraying | 1 | |

Reference Drying Data of Other Materials

Items | Inlet Air Temperature(°C) | Outlet Air Temperature(°C) | Raw Material Temperature(°C) | Raw Material Moisture Content(%) | Finished Product Moisture Content(%) | Product Particle Size(μm) | Bulk Density(kg/m3) |

Hydroxide Mud | 250 | 85 | 15 | 30 | 4.5 | 40 | 800 |

Dolomite | 310 | 145 | 15 | 66 | 0.4 | 15 | 450 |

Iron Oxide | 325 | 100 | 13 | 65 | 0.6 | 5 | 300 |

Aluminum Oxide | 250 | 90 | 18 | 71 | 12.5 | 70 | 400 |

Aluminum Silicate | 450 | 100 | 15 | 80 | 5.5 | 20 | 200 |

Calcium Carbonate | 280 | 90 | 13 | 42 | 0.3 | 50 | 450 |

Acid Yellow | 225 | 90 | 20 | 72 | 9 | 10 | 300 |

Tartrazine | 210 | 95 | 10 | 50 | 5 | 10 | 700 |

Calcium Stearate | 100 | 52 | 20 | 57 | 0.32 | 16 | ---- |

Starch | 120 | 63 | 20 | 42 | 12 | 30 | 610 |

Precipitated Calcium Carbonate | 120 | 70 | 0 | 33 | 0 | 5 | 800 |

Titanium Dioxide | 700 | 125 | 15 | 35 | 0.5 | 3 | 600 |