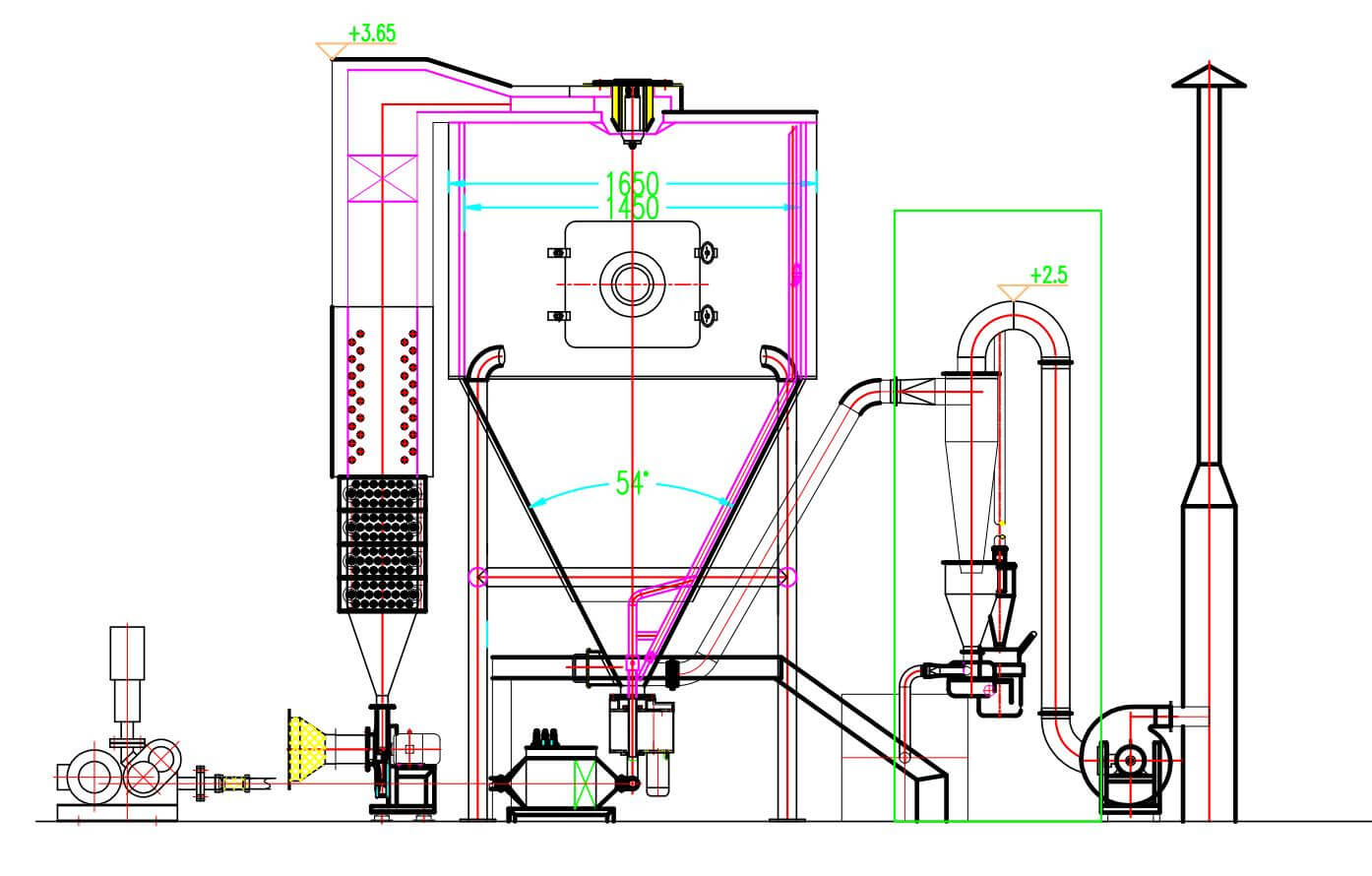

Centrifugal Spray Dryer Flow Chart

Technical Parameters

| Model Dimension | 5 | 25 | 50 | 150 | 200-2000 |

| Inlet Temperature | 140-350℃ automatic control | ||||

| Outlet Temperature | 80-90℃ | ||||

| Max. Evaporation Capacity (kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Atomizing Method | compressed air transmission | mechanical transmission | |||

| Revolution(r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Diameter of Atomizing Disc(mm) | 50 | 120 | 120 | 150 | 180-240 |

| Heat Source | electricity | steam+electricity | steam+electricity, oil, oil fuel, hot air furnace | ||

| Max. Heating Power(kW) | 9 | 36 | 72 | 99 | |

| Overall Dimensions(L*W*H)(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | depends on the actual situation |

| Dried Powder Restoring Rate(%) | ≥95 | ||||

Centrifugal Spray Drying Machine Composition

1. Feeding System

1.5kw, 0.8mpA motor variable frequency screw pump, the design temperature is under normal temperature conditions, if there is a temperature change, please contact us.

2. Hot Air System

This system provides the clean air needed before drying. The filtration volume is 25000m3/h, and the max pressure is 50Pa. The filter material is non-woven fabric, and the heating system adopts steam + electric heating.

3. Drying System

3.1 Inlet Volute

The stainless steel SUS304 logarithmic spiral hot air volute is at the top of the drying tower, providing stable hot air for the drying tower.

3.2 Drying Tower

The drying tower is a cylindrical tall cylinder with a conical bottom. The tower has hot air inlet and outlet, inspection and cleaning ports, observation holes, lighting holes, etc. The entire drying tower is mounted on a bracket.

The inner and outer walls of the tower are made of stainless steel SUS304. The insulation material is 100mm aluminum silicate (Al₂SiO₅).

Applications

1. Our LPG-200 Centrifugal Spray Dryer Drying Solution for Nutrient Compound

1. Customer Materials & Requirements | |

Material | Agricultural organic compounds |

Moisture state | Free water |

Evaporation | About 200kg/h |

Wet basis moisture content | 75% (free water) |

Dry basis moisture content | ≤3% (free water) |

Liquid specific gravity | 1.2kg/cm³ |

Feed Temperature | 10~12℃ |

Discharge Temperature | About 35℃ |

Heat Source | Gas hot blast stove |

Receiving Method | Cyclone + cooling centralized collection |

2. Drying Solution Technical Parameters | |

Equipment Model | LPG-200 Centrifugal Spray Dryer *1 |

Atomization Method | Centrifugal |

Hot Air Contact Method | Parallel flow |

Inlet Air Temperature | 160~220℃ |

Outlet Air Temperature | 80~100℃ |

Material requirements | Product contact SUS304 |

Dust Removal Method | Cyclone separator |

Heating Method | Gas hot blast stove |

Feeding Method | Screw pump feeding |

Installation Site | General area for the main tower, clean area for receiving materials |

Installation Site Size | Plant condition drawing is required |

Noise | <80 dB |

3. Public Works Conditions | |

Atmospheric Pressure | 101.3KPa |

Ambient Temperature | 10℃ |

Relative Humidity | 70% |

Electric Power | 380V, 3-phase, 50HZ |

Machine Power | About 50KW |

Compressed Air Consumption | 0.8m³/min |

Natural Gas Consumption | 42Nm³ /h |

Compressed Air Pressure | 0.3~0.6mpa |

2. Our LPG-2000 Centrifugal Spray Dryer Drying Solution for Mango Juice

1. Customer Materials & Requirements | |

Material | Mango juice |

Moisture state | Free water |

Evaporation | 2000kg/h |

Wet Bsis Moisture Content | 80% (free water) |

Dry Bsis Moisture Content | ≤5% (free water) |

Liquid specific gravity | 1.03kg/cm³ |

Feed Temperature | 40℃ |

Discharge Temperature | About 35℃ |

Heat Source | Steam + electric heating |

Receiving Method | Cyclone + Water film dust collector |

2. Drying Solution Technical Parameters | |

Equipment Model | LPG-2000 Centrifugal Spray Dryer *1 |

Atomization Method | Centrifugal |

Hot Air Contact Method | Parallel flow |

Inlet Air Temperature | 160~220℃ |

Outlet Air Temperature | 80~100℃ |

Material requirements | Product contact SUS304 |

Dust Removal Method | Cyclone separator |

Heating Method | Steam + electric heating |

Feeding Method | Screw pump feeding |

Installation Site | General area for the main tower, clean area for receiving materials |

Installation Site Size | Plant condition drawing is required |

Noise | <80 dB |

3. Public Works Conditions | |

Atmospheric Pressure | 101.3KPa |

Ambient Temperature | 10℃ |

Relative Humidity | 70% |

Electric Power | 380V, 3-phase, 50HZ |

Machine Power | About 230KW |

Compressed Air Consumption | 0.6m³/min |

Steam Consumption | About 3500kg/h |

Compressed Air Pressure | 0.3~0.6mpa |

3. Our TPG-1000 Centrifugal Spray Dryer Drying Solution for Fish Hydrolyzed Protein

1. Customer Materials & Requirements | |

Material | Fish hydrolyzed protein |

Moisture state | Free water |

Evaporation | About 1000kg/h |

Wet Base Moisture Content | 79% (free water) |

Dry Base Moisture Content | ≤3% (free water) |

liquid specific gravity | 1.04kg/cm³ |

Feed Temperature | 10~12℃ |

Discharge Temperature | About 35℃ |

Heat Source | Gas hot blast stove |

Receiving Method | Two-stage cyclone collector |

2. Our Drying Solution Technical Parameters | |

Equipment Model | TPG-1000 Centrifugal Spray Dryer *1 |

Atomization Method | Centrifugal |

Hot Air Contact Method | Parallel flow |

Inlet Air Temperature | 160~220℃ |

Outlet Air Temperature | 80~100℃ |

Material requriments | Product contact SUS304 |

Dust Removal Method | Cyclone separator |

Heating Method | Gas hot blast stove |

Feeding Method | Screw pump feeding |

Installation Site | General area for the main tower, clean area for receiving materials |

Installation Site Size | Plant condition drawing is required |

Noise | <80 dB |

3. Public Works Conditions | |

Atmospheric Pressure | 101.3KPa |

Ambient Temperature | 10℃ |

Relative Humidity | 70% |

Electric Power | 380V, 3-phase, 50HZ |

Machine Power | 120KW |

Compressed Air Consumption | 1.1m³/min |

Natural Gas Consumption | About 116Nm³ /h |

Compressed Air Pressure | 0.3~0.6mpa |