Working Principle

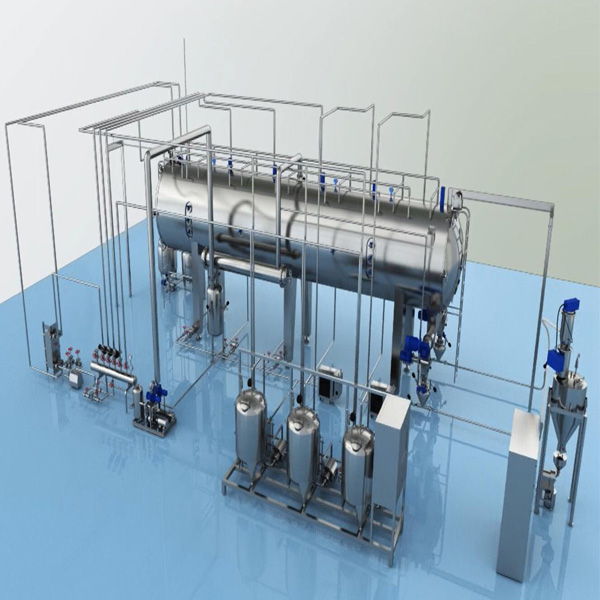

It is a vacuum drying equipment with continuous feeding and continuous discharging. The raw material to be dried is transported into the dryer by the feed pump and evenly distributed on the conveyor belt by the distributor, and the boiling point temperature of the material is lowered by the high vacuum, and the moisture of the liquid raw material is directly sublimated to the vapor, and the conveyor belt is on the heating plate.

It runs at a constant speed, and the heat source in the heating plate can be heated by steam, hot water or electric heating. Through the operation of the conveyor belt, from the evaporation and drying at the front end to the cooling discharge at the back end, the temperature range from high to low can be adjusted according to the characteristics of the material., the discharge end is equipped with a specific vacuum pulverizing device to achieve finished products of different particle sizes, and the dried powder can be automatically packaged or processed later.

Applications

It is suitable for drying maltose, malt milk, sucrose, beet sugar, dextrin, oatmeal, corn steep liquor, rice flour, honey, coffee and other sugars and various substances with high sugar content. The high-concentration, high-viscosity Chinese herbal extract solves a major problem.

This machine is not only suitable for sugar food and traditional Chinese medicine extracts, but also suitable for low-temperature drying of various liquid paste-like raw materials such as Chinese and Western medicines, polysaccharide medicines, bioengineering, chemical raw materials, food additives, etc., Easy to agglomerate, thermoplastic, heat-sensitive products drying; welcome new and old customers to bring materials to the company to test the machine.